Situation

Several top-driven stirred tank reactors, which are run discontinuously in batch operation

Sealing solution for a polymer dispersion plant

Several top-driven stirred tank reactors, which are run discontinuously in batch operation

High pressures and temperatures; a standstill of the stirred tank reactor during the chemical process has to be avoided at all costs

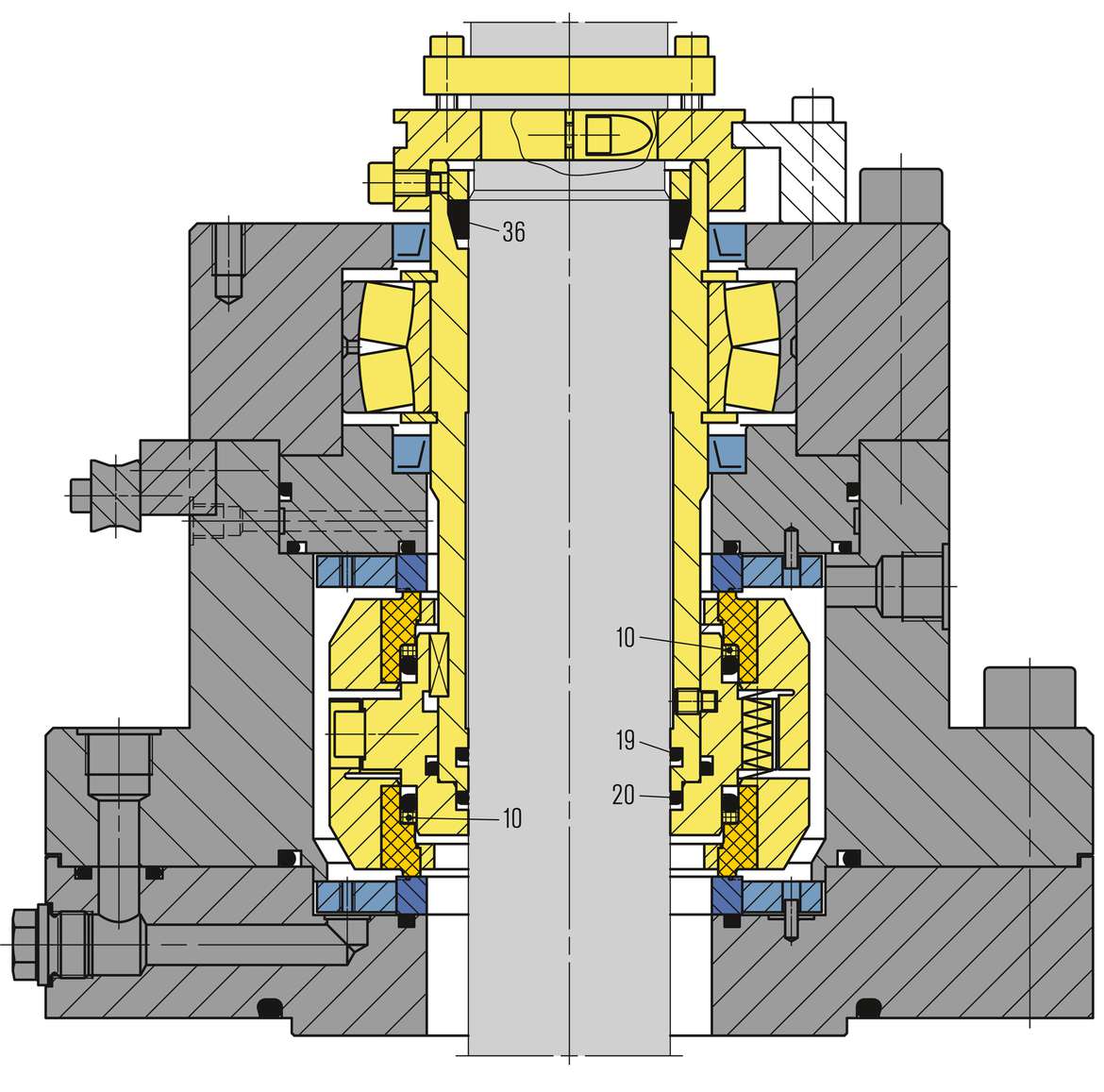

HSHLV-D agitator seals to seal the stirred tank reactor, and mechanical seals Typ M481 in the reactors storage tanks

In a production facility for aqueous polymer dispersions, several stirred tank reactors are run discontinuously in batch operation. This means that the tank is filled at the beginning of the process and then set to the required operating conditions. Diverse monomers and water are used as raw materials. Through polymerization they react to form polymers which at the end of the reaction exist in aqueous solution as a dispersion.

The agitator is not allowed to stop while the reaction is in progress as this could result in a runaway reaction, i.e. overheating and even uncontrolled release of chemicals. Thus, the agitator seal must be especially reliable and have considerably higher lifetimes. The second factor to be considered are pressures up to 100 bar that have to be handeled by the implemented seal.

The first stirred tank reactors, in use since the early 80’s, were originally fitted with other seal types from a competitor. Already in the 80’s these were converted to EagleBurgmann seals, which lead to a significant increase of the lifetime. By further optimization regarding construction details and material selection the lifetime could be further increased. To keep the level of the best available technology a new seal type, the HSHLV-D was tested. With it an average MTBF of 2 to 3 years was achieved. One seal set a new lifetime record of more than 4 years.

Download the solution flyer

In Great Britain, a shortage in natural gas supply has severe consequences: Since the country switched from coal-fired to gas-fired power stations, a gas supply shortage makes households and industrial consumers not only vulnerable to failing heating and gas stoves, but also to power outages. Companies along the value and transportation chain of natural gas are therefore especially dependent on reliable equipment.

A boiler circulation pump in a power plant conveys very hot and pressurized water. The pump has no cooling jacket, which increases the risk of a thermosiphon effect.

By means of custom-made PLUG & RUN expansion joints with a more wear-resistant material, EagleBurgmann was able to provide a solution which ideally fulfills the requirements with regard to wear while at the same time significantly reducing the changeover time.

Reliability during sensible chemical reaction processes and a significantly increased lifetime characterize the agitator seal used in a chemical production plant. In stirred tank reactors of a polymer dispersion facility in Germany, various monomers and water are transformed into polymers. EagleBurgmann HSHLV-D agitator seals are used in these reactors to prevent standstills.

Mechanical seals are not always the best choice. In roller dryers used in the production of pharmaceutical powder, abrupt shaft deflections during processing led to increased seal wear. Operation was maintenance-intensive and prone to faults.

Special expansion joints from EagleBurgmann compensate for these position changes and work reliably even under unfavorable conditions such as low temperatures, proximity to the sea and explosive environments.