Situation

Temperature layering can damage the pump shaft and seal

Temperature layering can damage the pump shaft and seal

Prevent exchange of cold and warm water on the shaft without cooling jacket

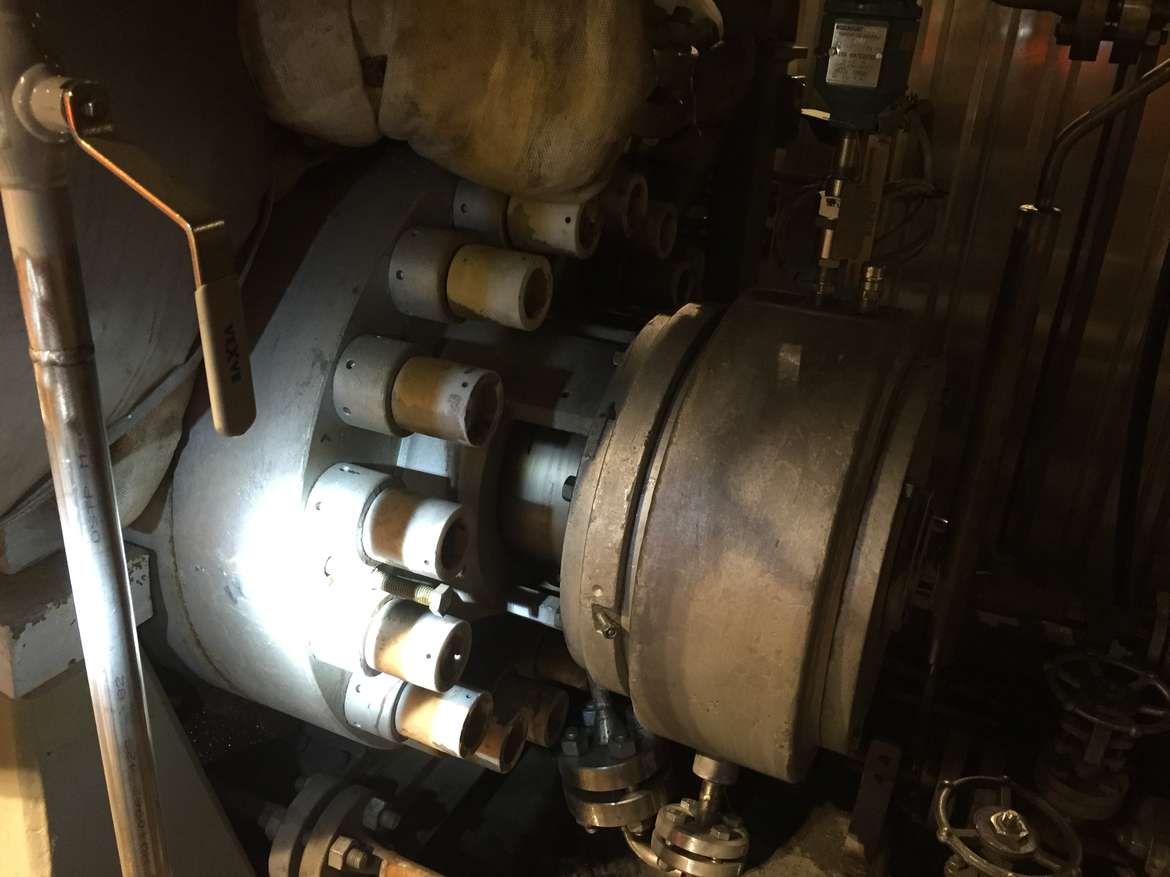

Mechanical seal SHFVI and screw pump HPS from EagleBurgmann

Waste, natural gas, coal, wood and biogas are the fuels used by a Finnish power supplier to produce electricity and district heating in two power plants. The seals of a boiler circulation pump in the coal-fired block must function properly up to 300 °C and at a pressure of up to 150 bar.

This pump delivers very hot boiler water to a steam boiler, and the seal prevents the hot and pressurized boiler water from escaping as steam at the pump shaft. The seal therefore plays an immense role in the safety of power plant personnel. Likewise, the availability of the power plant and the reliable generation of electricity and district heating also depends on functioning pumps and seals.

A market player had initially equipped the pump with mechanical seals. But they failed unexpectedly regularly within three to six months after commissioning. This resulted in several dangerous steam leaks. Luckily the plant personnel were not injured, but the seal failures incurred immense costs. The power plant operator then commissioned a different pump manufacturer to offer a new pump. But it was determined that the use of a new pump was not feasible for design reasons. And so this renowned manufacturer approached EagleBurgmann with the aim of collaborating closely to develop a permanently safe sealing solution.

The project began with an investigation into the root cause of the seal failure. The original seal supply included a cooling circuit in accordance with API Plan 23. This cooling circuit was equipped with a large heat exchanger. However, the pump had no cooling jacket - a fact that EagleBurgmann also had to take into account.

The mechanical seal SHFVI from EagleBurgmann is the ideal product for applications under extreme conditions - at high pressures up to 150 bar (2,175 PSI) and temperatures up to 350 °C (662 °F). It was optimized to withstand the deformation caused by frequent starts and stops. For quick and easy installation, it is supplied as a pre-assembled unit. The specifically designed connection parts have been adapted to the pump installation space.

A seal face developed for boiler feed and boiler circulation pumps and designed for high pressures was selected for use in this boiler feed pump. The design of the rotating seat and the integrated pumping screw ensure optimum heat dissipation from the seal.

Operating conditions:

During standstill at high temperatures, typically a thermosiphon effect occurs. Due to this effect, warm water is at the top of the pump shaft and relatively cold water at the bottom. This can lead to temperature layering and cause distortion of seal parts, the pump shaft and the pump housing. EagleBurgmann therefore installed a Thermo Stop to prevent such damage.

A segmented carbon ring with lift-off grooves prevents the exchange of cold and warm water and thus temperature layering. No leakage occurs during standstill periods, which prevents the carbon seal rings from eroding.

The SHFVI seal also requires a cooling circuit via an external cooler in accordance with API Plan 23. This allowed the existing cooling circuit to be used. However, neither the seal nor the pump housing had enough space for the required cooling jacket. EagleBurgmann then decided to use an external screw pump of the HPS series to replace the necessary jacket cooling by forced circulation in Plan 23 for standstill. This screw pump is hermetically sealed and largely maintenance-free.

After two years of trouble-free use, the operator of the power plant and the pump manufacturer were so satisfied with the EagleBurgmann solution that another pump was retrofitted. The SHFVI seal has also been successfully used in boiler feed and boiler circulation pumps of other power plant operators.

Do you have similar requirements? Please contact us.

In Great Britain, a shortage in natural gas supply has severe consequences: Since the country switched from coal-fired to gas-fired power stations, a gas supply shortage makes households and industrial consumers not only vulnerable to failing heating and gas stoves, but also to power outages. Companies along the value and transportation chain of natural gas are therefore especially dependent on reliable equipment.

A boiler circulation pump in a power plant conveys very hot and pressurized water. The pump has no cooling jacket, which increases the risk of a thermosiphon effect.

By means of custom-made PLUG & RUN expansion joints with a more wear-resistant material, EagleBurgmann was able to provide a solution which ideally fulfills the requirements with regard to wear while at the same time significantly reducing the changeover time.

Mechanical seals are not always the best choice. In roller dryers used in the production of pharmaceutical powder, abrupt shaft deflections during processing led to increased seal wear. Operation was maintenance-intensive and prone to faults.

Special expansion joints from EagleBurgmann compensate for these position changes and work reliably even under unfavorable conditions such as low temperatures, proximity to the sea and explosive environments.

The Etzel oil and gas cavern system is situated southwest of Wilhelmshaven, not far from the North Sea coast. A vast salt dome houses the more than 70 caverns which store crude oil and natural gas at depths between 900 and 1,700 meters. Etzel is integrated in the northwest European oil and gas pipeline network and makes a significant contribution to the safe and reliable supply of gas to Germany and all of Europe.