Buralloy

Ring Type Joint 2961

Buralloy

Ring Type Joint 2961

Buralloy

Ring Type Joint 2961

Features

Buralloy ring-type joint 2961 (RTJ) gaskets are manufactured from metallic materials in compliance with American standard ASME B 16.20 and the API specification. Detailed monitoring of every manufacturing step guarantees that the sealing rings offer the necessary surface hardness. This creates a functional seal without damage to the flanges. This gasket type is used successfully in downstream refinery applications, for example. RTJ gaskets are also commonly used in high-pressure valves and the associated pipe connections and in pressure vessel joints.

Advantages

- Metal-to-metal contact creates a reliable seal

- Suitable for extreme pressure and temperature requirements

- Certified quality (including surface hardness)

Materials

RTJ gaskets are available as standard in soft metal and in 304, 316 and stainless steels. Versions in other materials on request.

Standards and approvals

All RTJ gaskets are manufactured to API standards, guaranteeing consistent quality.

Recommended applications

Industries

- Oil & gas industry

- Petrochemical industry

- Flange connections

- Pipe connections

Functional description

Under axial compressive load, ring type joints plastically deform and flow into the irregularities of the flange groove. Since the contact area of the ring type joint is relatively small, a very high compressive load results between the sealing surface of the ring type joint and the flange groove. This surface pressure is further increased especially by the RX and BX RTJ variants. Both variants are able to seal extremely high internal pressures. RTJ gaskets are produced from metal, so they remain in their compressed form, even when the surface pressure is relaxed. The sealing function of the RTJ gasket is reinforced by the axial forces acting on the sealing surfaces.

Forms of supply

- Standard dimensions as per DIN EN 12560-5 or ASME B16.20

- RTJ gaskets are available from stock in ½” to 36” and 15 mm to 900 mm sizes, and in the commonly available materials to suit most ASME and DIN flange dimensions. Larger sizes and special requirements are available to order.

Product variants

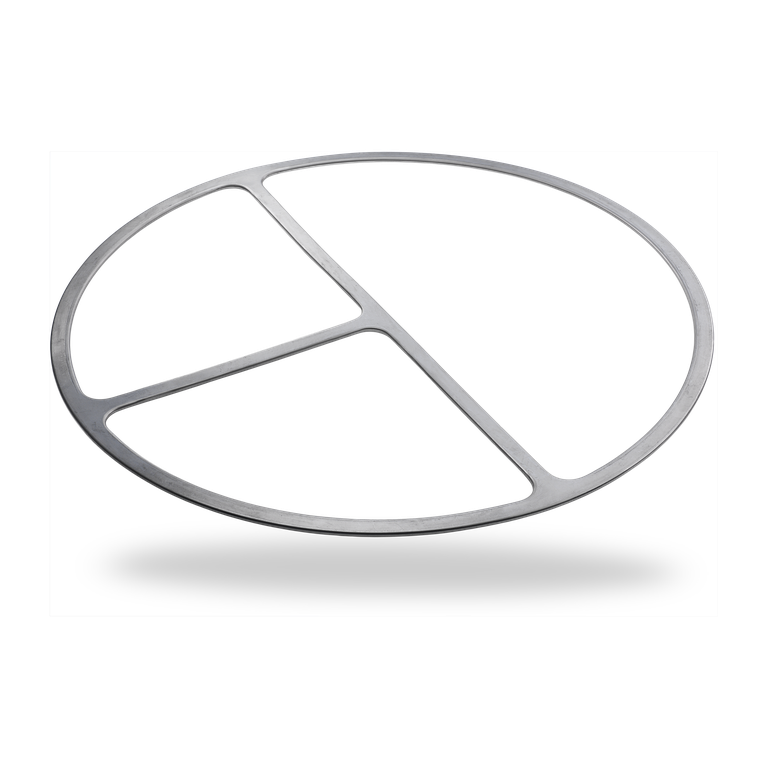

Buralloy Ring Type Joint 2961/R

Style R ring type joints are manufactured on oval (2962/R) and octagonal profiles (2961/R).

Both styles are interchangeable in the modern flat bottomed groove.

Octagonal profile joints are interchangeable on flat bottomes groove flanges which have a 23 degree angle groove wall

Style R ring type joints are designed to seal pressures up to 6,250 PSI (425 bar) in accordance with ASME B 16.5

ratings and up to 5,000 PSI (340 bar) in accordance with API 6A pressure ratings.

Style R ring type joints are manufactured on oval (2962/R) and octagonal profiles (2961/R).

Both styles are interchangeable in the modern flat bottomed groove.

Octagonal profile joints are interchangeable on flat bottomes groove flanges which have a 23 degree angle groove wall

Style R ring type joints are designed to seal pressures up to 6,250 PSI (425 bar) in accordance with ASME B 16.5

ratings and up to 5,000 PSI (340 bar) in accordance with API 6A pressure ratings.

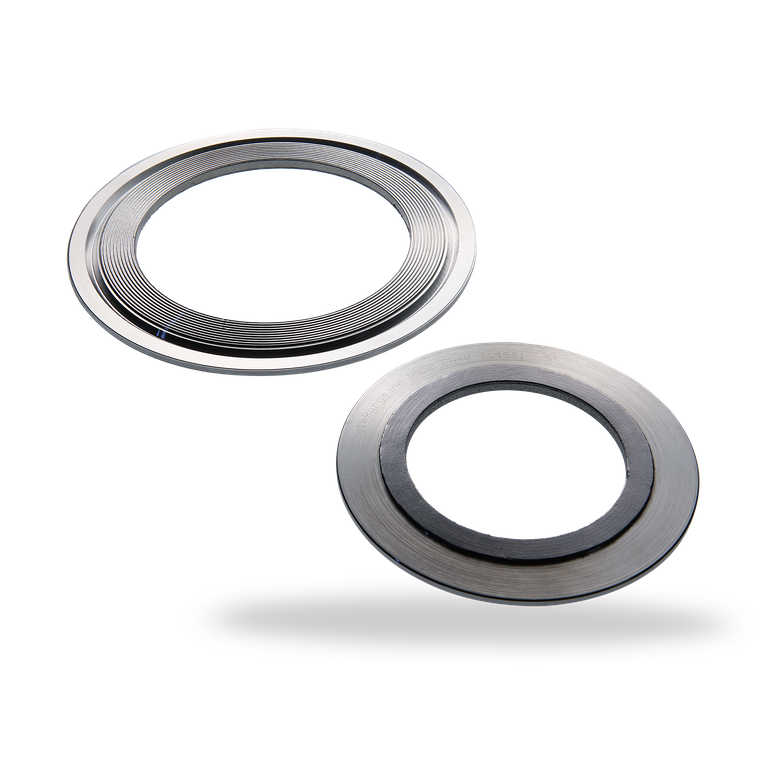

Buralloy Ring Type Joint 2961/RX

Designed for pressures up to approx. 10,000 psi (700 bar). This is self-sealing that uses a pressure-energised effect.

The Style RX ring type joint is manufactured in accordance with API 6A and ASME B 16.20, to suit API 6B and ASME B 16.5 flanges.

The Style RX is designed to fit the modem flat bottom groove, and is inter¬changeable with the standard Style R ring type joint.

However, since the Style RX is significantly taller than a Style R, larger flange make-up distances will result.

Style RX ring type joints are designed to seal pressures up to 6,250 PSI (425 bar) in accordance with ASME B16.5 pressure ratings, and up to 5,000 PSI (340 bar) in accordance with API 6A pressure ratings.

Selected sizes incorporate a pressure passage hole to allow for pressure equalization each side of the sealing faces.

Designed for pressures up to approx. 10,000 psi (700 bar). This is self-sealing that uses a pressure-energised effect.

The Style RX ring type joint is manufactured in accordance with API 6A and ASME B 16.20, to suit API 6B and ASME B 16.5 flanges.

The Style RX is designed to fit the modem flat bottom groove, and is inter¬changeable with the standard Style R ring type joint.

However, since the Style RX is significantly taller than a Style R, larger flange make-up distances will result.

Style RX ring type joints are designed to seal pressures up to 6,250 PSI (425 bar) in accordance with ASME B16.5 pressure ratings, and up to 5,000 PSI (340 bar) in accordance with API 6A pressure ratings.

Selected sizes incorporate a pressure passage hole to allow for pressure equalization each side of the sealing faces.

Buralloy Ring Type Joint 2961/BX

The Style BX ring type joint is manufactured in accordance with API 6A.

All BX ring type joints incorporate a pressure passage hole to allow for pressure equalization each side of the sealing faces. On assembly, metal to metal contact of the flange faces is achieved.

The Style BX is not interchangeable with any other style, and is only suited for API 6BX flanges. Style BX ring type joints are designed to seal pressure up to 20,000 PSI (1,360 bar) in accordance with API 6A pressure ratings.

Styles SRX and SBX are derived from Styles RX and BX, and are produced in line with the API Standard 17 D for use on subsea wellhead and Christmas tree equipment.

The Style BX ring type joint is manufactured in accordance with API 6A.

All BX ring type joints incorporate a pressure passage hole to allow for pressure equalization each side of the sealing faces. On assembly, metal to metal contact of the flange faces is achieved.

The Style BX is not interchangeable with any other style, and is only suited for API 6BX flanges. Style BX ring type joints are designed to seal pressure up to 20,000 PSI (1,360 bar) in accordance with API 6A pressure ratings.

Styles SRX and SBX are derived from Styles RX and BX, and are produced in line with the API Standard 17 D for use on subsea wellhead and Christmas tree equipment.

Similar products

Buralloy Heat exchanger seal 2500

The Buralloy heat exchanger seal 2500 is a semi-metal gasket with a soft core and metal jacketing. The Buralloy 2500 thus combines the benefits of a compressible soft seal with the mechanical strength of a metal seal. As a result, it can be produced in many different material combinations and in different styles to suit the application.

Camprofile serrated gasket 9588

The serrated gasket 9588 has a concentrically-machined profile based on a 4 mm thick stainless steel base plate. This is coated on both sides with a 0.5 mm thick layer of pure graphite (purity > 98%). Thicker layers are available on request. The serrated gasket 9588 is easy to handle and is particularly suitable for applications in the chemical and petrochemical industries and in power station technology.

Corrachem 9631/T corrugated gasket

The Corratherm 9631/T corrugated gasket is a high-quality two-component gasket made from PTFE and stainless steel. Its core is consists of a corrugated stainless steel profile ring with PTFE on both sides. Gaskets with an outer diameter up to 1,000 mm are produced in a single piece, while for larger dimensions, the metal base plate must be produced in multiple segments and welded together.